Specifications

1.Mini Removable Desiccant Rotor Dehumidifier

2.Suitable for low temperature and humidity process

3.Silica gel desiccant wheel

Character

1) Dehumidify quickly, suitable for low temperature and humidity process.

2) Silica gel desiccant wheel, chain-driven.

3) Aluminum frame.

4) Inner insulation box, energy-saving.

5) Efficient centrifugal fans.

6) Thermal regeneration by electric heating pipe and stainless steel fins, thermal regeneration by vapor heating exchanger and copper tube aluminum fins.

7) Safe and convenient electric control.

8) Switch between manual and automatic control.

Model Example

ZLKD-1000

ZL: Basic Code for Rotary Dehumidifier

K: Combination Code for Adsorbent, K for Fixing, S for Welding.

D: Rotary regeneration type. D for Electricity, Z for Steam.

1000: Process airflow m3/h

Main Parameters of ZL Series Dehumidifier

| Main Parameters/Model |

ZLK-200 |

| Proecess Air |

Rated Airflow(m3/h) |

200 |

| Process ESP(Pa) |

/ |

| Reactivation Air |

Rated Airflow(m3/h) |

66 |

| Process ESP(Pa) |

/ |

| Reactivation Mode |

Electric, Max Power (kW) |

1.0 |

| Steam Pressure (Mpa) |

/ |

| Steam, Steam Consumption(kg/h) |

/ |

| Dehumidifying Capacity (20°C,70%) (kg/h) |

1.0 |

| Drive Motor |

Motor Power (kW) |

0.015 |

| Installed Power (kW) |

Electric Heating Mode |

1.206 |

| Steam Heating Mode |

/ |

Overall Dimensions

(mm) |

Length |

525 |

| Width |

372 |

| Height |

382 |

| Approx. Weight (kg) |

30 |

Note:

1. Air flow above 4000 without process fan, users can select.

2. If regeneration heating type select steam, P=0.4MPa.

3. Larger airflow dehumidifiers can be customized.

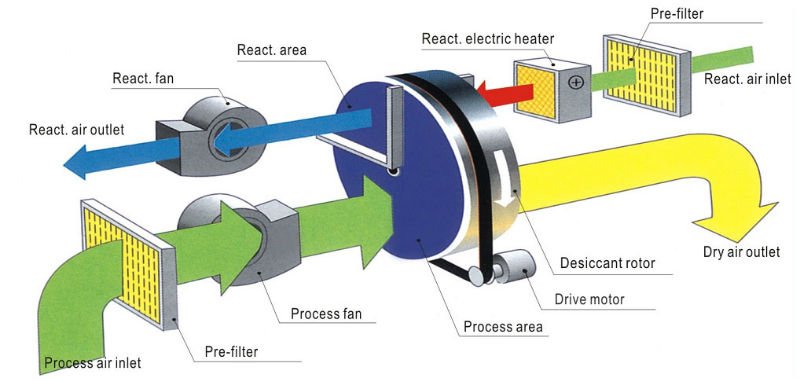

Work Principle

The core component of rotary dehumidifier is the 8-16 hour spin in turn densely cellular Conde desiccant wheel. The desiccant wheel on both sides by high-performance silicon fluorine rubber seals along the entire surface of the radial will be divided into 270 ° of the treatment area and 90 ° of the regeneration zone, when the moist air comes into the processing area, the air moisture in the desiccant wheel was adsorbed into dry air, dry air meet the need of dry place or gas production process.

absorption process, desiccant wheel gradually loss of moisture absorption capacity. In order to maintain constant moisture absorption capacity, rotary should be regenerated. So, tending to saturation the drive wheel driven by the motor slowly turns into the regeneration area, regeneration restored.

Heated to 100-140 °C,the regeneration air and deal with the wind in the opposite direction enters into the regeneration zone, the moisture desorption in the wheel takes exhausted to outside by renewable wind. Desiccant wheel restore moisture absorption capacity and under the drive of low-level driver enters into the handling area to process and absorb the wind again.

When wheel rotate constantly, dehumidify and regeneration continues. Thus, exporting the constant humidity and dry air won’t stop.

Main Accessories

Desiccant rotor, Process Fan, React. Fan

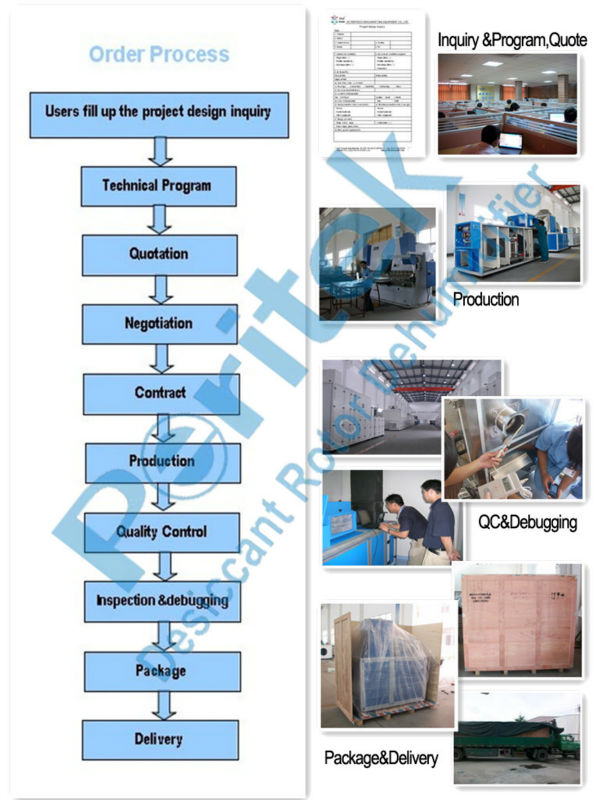

After inspection and debugging, the dehumidifiers are packed by stretch film and then carefully packed and fixed cartons

How to order

Since we have series dehumidifiers depends on different demands, we need to know some detailed information of your demand, we will send you a project design inquiry for your first inquiry, you can fill it, so that we couldmake a technical program and quotation as per your actual requirements asap.

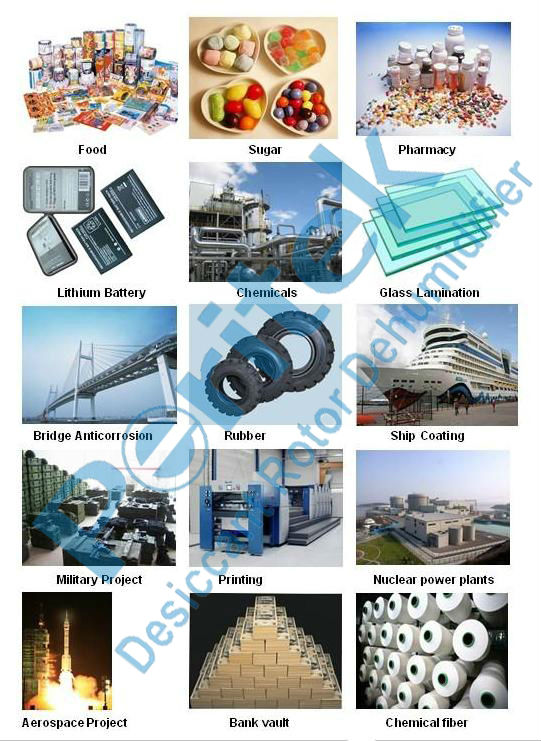

Application