Description:

The Dehumidifier is specialized for normal temperature and low humidity process environment. Its major characteristics are as follow:

1. Main components: pre-filter, desiccant rotor, process fan, electric controller and cabinet.

2. The cabinet is made of aluminum alloy, and double insulation panel structure with high density polyurethane insulation material inside, strong, compact, anti-corrosion, and it is anti-“cold bridge” which can help avoid condensating.

3. The dehumidifier select PROFLUTE silica gel desiccant wheel from Sweden.

4. Select centrifugal fan, its impeller and vent was plated with anti-corrosion coating, it’s strong and anti-corrosion.

5. G4 rough effect air filters to assure air purity.

6. Use text display, temperature and humidity probe to control temperature and humidity. It is convenient to operate.

Main Parameters of ZL Series Dehumidifier

| Main Parameters / Model |

ZLK-D-3000 |

ZLK-D-5000 |

ZLK-D-8000 |

ZLK-D-10000 |

ZLK-D-20000 |

ZLK-D-30000 |

| Process Air |

Airflow m³/h |

3000 |

5000 |

8000 |

10000 |

20000 |

30000 |

| |

Fan Power kW |

2.2 |

|

/ |

/ |

/ |

/ |

| Reactivation Air |

Airflow m³/h |

1000 |

1670 |

2670 |

3330 |

6670 |

10000 |

| |

Fan Power kW |

1.1 |

1.5 |

2.2 |

3 |

5.5 |

11 |

| Reactivation Mode |

Electrical Heating Power kW |

25.2 |

36 |

66 |

84 |

156 |

240 |

| |

Steam Consumption kg/h |

42 |

60 |

110 |

140 |

260 |

400 |

| Dehumidify Capacity kg/h |

20°C,70% |

21.7 |

36.2 |

58.0 |

72.5 |

145.0 |

217.4 |

| Drive Motor Power kW |

0.09 |

0.04 |

0.12 |

0.18 |

0.25 |

0.25 |

| Installed Power |

Electrical Heating kW |

28.59 |

44.32 |

68.32 |

87.18 |

161.75 |

251.25 |

| |

Steam Heating kW |

3.39 |

2.32 |

2.32 |

3.18 |

5.75 |

11.25 |

| Overall Dimensions |

Length mm |

1680 |

1760 |

1760 |

1800 |

2020 |

2320 |

| |

Width mm |

1030 |

1330 |

1430 |

1630 |

2180 |

2460 |

| |

Height mm |

1570 |

2230 |

2610 |

2810 |

3300 |

3600 |

| Weight kg |

400 |

120 |

750 |

850 |

1250 |

1800 |

1. Air flow above 4000 without process fan, users can select.Note:

2. If regeneration heating type select steam, P=0.35~0.45MPa.

3. Larger airflow dehumidifiers can be customized.

Competitive Advantage:

1. Peritek dehumidifiers are manufactured based on more than 30 years of research and development. Have been used in space suit specific cell production and become the most advanced satellite transmission tower supporting equipment.

2. Peritek dehumidifiers with R-DD optimal design, compared with the general dehumidifier, can save energy more than 35%, and above 10% with heat exchanger dehumidifiers.

3. Dehumidification ability of Peritek dehumidifiers is great. Under normal use, after closing down for 10 hours, system can restart and reach the technical target in 30 to 60 minutes.

4. We can provide users domestic initiative remote communication interface according to your requirements, and the remote computer operation and management system networking, superior to realize remote service.

5. Peritek dehumidifiers adopt steel structure with plastic-sprayed surface (Peritek self-owned patent, patent number: ZL 2008 0163177.3 2).

Work Principle:

The core component of rotary dehumidifier is the 8-16 hour spin in turn densely cellular Conde desiccant wheel. The desiccant wheel on both sides by high-performance silicon fluorine rubber seals along the entire surface of the radial will be divided into 270 ° of the treatment area and 90 ° of the regeneration zone, when the moist air comes into the processing area, the air moisture in the desiccant wheel was adsorbed into dry air, dry air meet the need of dry place or gas production process.

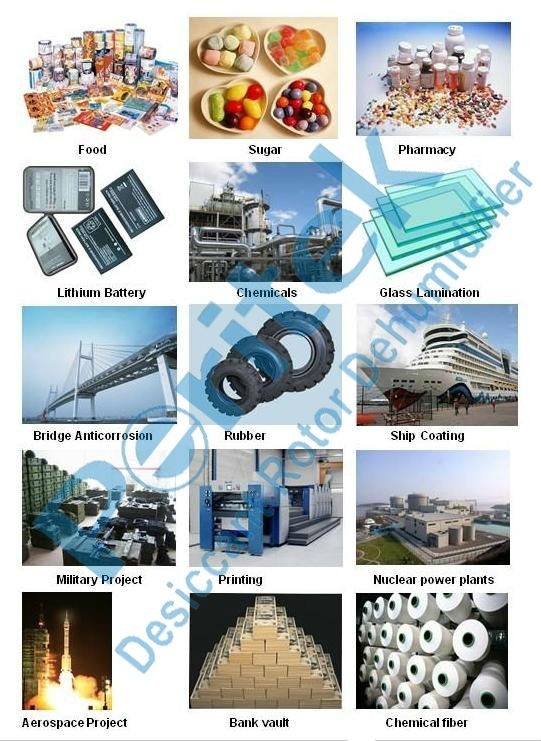

Typical Application Fields:

1. Warehouse, Library and Archives:

In low humidity environment, the goods, books and files will not be damaged for a long time.

2. Pharmaceutical Industry:

Widely used in processes need to control humidity in parametrical industries, for example, soft gelatin capsule, fluidized bed, tablet press, coating machine, tumble dryer, tray dryer and so on.

3. Electronics Industry, Lithium Battery

It is widely used for precision instrument manufacture such as electronic components, astronavigation component, lithium battery etc which needs strict control of moisture.

4. Chemical Fiber Industry:

Used with chiller, it can make the dew point below -40℃ to meet the drying environment for PET chip in the chemical fibre factory.

5. Food Processing Industry:

Used in dehydrated vegetables, chocolate, candy, chewing gum manufacturing, cube

sugar store,flour processing, fermentation, drying and other processes.

6. Space and Aviation:

7. Glass Lamination

8. Ship Coating

9. Bridge Anticorrosion

10. Rubber Tire

11. Nuclear power plants

12. Printing

Packaging & Shipping: